Sintered SmCo Magnets

Item specifics

- Material

- Sm2Co17 ,SmCo5

- Shape

- Main Disc, but Block or Rectangular or Cuboid, Ring, Cylinder, Arc and Irregular shape are also available

- Coating

- Ni, Ni-Cu-Ni, Electroless Nickel, Zinc, Colored Zinc, Epoxy

- Magnetized direction

- Axially or Diametrical Magnetized, but Thickness, Multipoles and Radial magnetization are also available

- Certificate

- ISO/TS 16949, ISO9001, ISO14001, RoHS, REACH

- Packing

- Standard sea or air packing, such as carton, wooden box, pallet etc

Review

Description

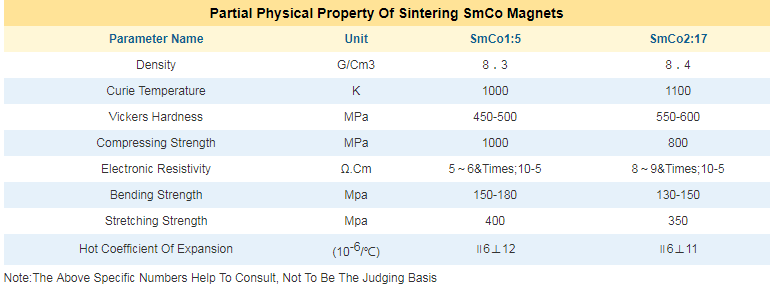

SmCo 1:5

As the nomination indicates, the samarium–cobalt 1:5 magnet alloys (generally written as SmCo5, or SmCo 1:5) have one atom of rare earth samarium per five atoms of cobalt. By weight this magnet alloy will typically contain 36% samarium with the balance cobalt. Sometimes Prasedymium is alloyed to increase the remanence. The energy products of these samarium–cobalt alloys range from 16 MGOe to 25 MGOe, that is, approx. 128 - 200 kJ/m3. Contrary to SmCo 2:17 magnets, the 1:5 magnets are relatively easy to magnetize and saturation magnetization can be achieved with a moderate magnetizing field. Therefore, 1:5 magnets are easier to calibrate to a specific magnetic field than the SmCo 2:17 magnets.

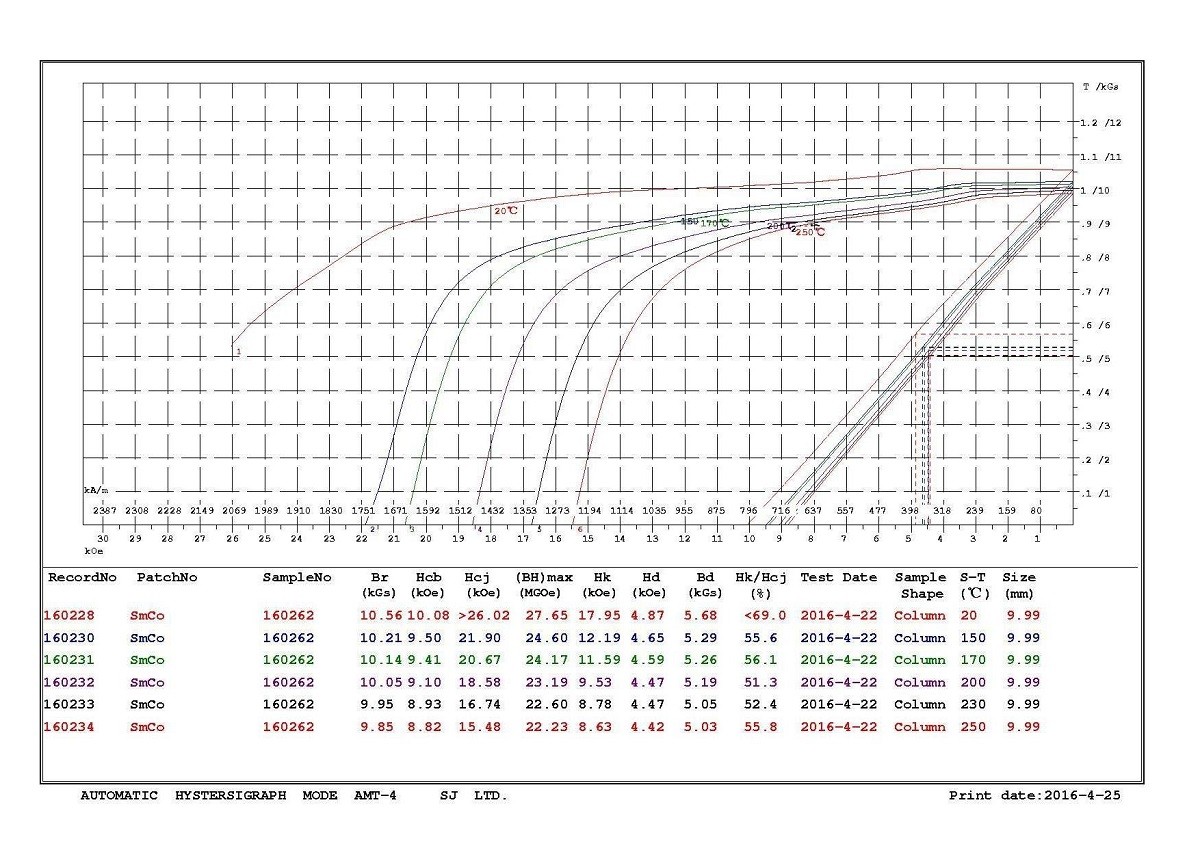

SmCo 2:17

These alloys (written as Sm2Co17, or SmCo Series 2:17) are age-hardened with a composition of two atoms of rare-earth samarium per 13–17 atoms of transition metals (TM). The TM content is rich in cobalt, but contains also other metals such as iron and copper. Other elements like Zirkonium and Hafnium etc. may be added in small quantities to achieve better heat treatment response. The maximum energy products of these alloys range from 20 to 32 MGOe, what is about 160-260 kJ/m3. These alloys have the best reversible temperature coefficient of remanence of all rare-earth alloys, typically being -0.03%/°C.

In Sm2Co17 magnets, the coercivity mechanism is based on domain wall pinning (in contrary to SmCo 1:5 and NdFeB where it’s nucleation). The purpose of alloying and heat treatment is to create a microstructure inside the magnets which impede the domain wall motion and thereby resist the magnetization reversal process.

Samarium Cobalt Magnets are among the second most common rare earth magnets.Grades and shapes of SmCo magnets are varied, so they can suit a wide variety of application requirements. Magnets can be shaped and sized in any configuration you can imagine in our custom machining shop. The maximum grade of a SmCo magnet is 32MGOe.

Common applications include use in the automotive, marine, medical, aerospace, military, industrial automation and similar industries where high performance is critical. Think pumps, motors, machinery, medical devices and so on.

Safety procedures are important to maintain, as these magnets can snap together with great force. They are also hard and brittle, and can shatter into sharp, dangerous objects. They have been known to chip when snapping together from large distances, but also when dropped at an unfortunate angle. Make sure all personnel handling these magnets can handle with care.

Compared with Neodymium?

SmCo magnets are not as high in energy as Neodymium magnets, but they excel in high temperature conditions where Neodymium magnets do not.SmCo magnets are the more expensive of the two, but is by far the best product when power and high temperature resistance is required.