Alnico is an acronym referring to a family of iron alloys which in addition to iron are composed primarily of aluminium (Al), nickel (Ni) and cobalt (Co), hence al-ni-co. They also include copper, and sometimes titanium. Alnico alloys are ferromagnetic, with a high coercivity (resistance to loss of magnetism) and are used to make permanent magnets. Before the development of rare earth magnets in the 1970s, they were the strongest type of magnet. Other trade names for alloys in this family are: Alni, Alcomax, Hycomax, Columax, and Ticonal.

The composition of alnico alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the balance is Fe. The development of alnico began in 1931, when T. Mishima in Japan discovered that an alloy of iron, nickel, and aluminum had a coercivity of 400 oersted (Oe; 32 kA/m), double that of the best magnet steels of the time.

AlNiCo can be divided to cast AlNiCo and sintered AlNiCo. When compared with cast AlNiCo, sintered AlNiCo perform with lower magnetic properties but better mechanical properties. AlNiCo are brittle and hard, not suitable for traditional maching processes except grinding processing.

铸造铝镍钴磁性能参数

Cast AlNiCo Magnetic Property Table

牌号 Grade | 分类 MMPA CLASS | 剩磁 Br Residual Induction | 磁感矫顽力 Coercive Force | 最大磁能积 (BH)max Max Energy Product | 居里温度 Curie temperature | 工作温度 Working Temperature |

Br | Hcb | ( BH ) max | (Tc) | Tw |

mT | (kGs) | kA/m | (kOe) | kJ/m3 | (MGOe) | [℃] | [℃] |

Typ. | Typ. | Typ. | | |

LN10 | ALNICO3 | 600 | 6000 | 40 | 500 | 10 | 1.25 | 750 | 550 |

LNG10 | 600 | 6000 | 44 | 550 | 10 | 1.25 | 750 | 550 |

LNG12 | ALNICO2 | 700 | 7000 | 44 | 550 | 12 | 1.5 | 800-850 | 550 |

LNG13 | 680 | 6800 | 48 | 600 | 13 | 1.63 | 800-850 | 550 |

LNG16 | ALNICO4 | 800 | 8000 | 48 | 600 | 16 | 2.00 | 800-850 | 550 |

LNG18 | 900 | 9000 | 48 | 600 | 18 | 2.25 | 800-850 | 550 |

LNG37 | ALNICO5 | 1200 | 12000 | 48 | 600 | 37 | 4.63 | 800-850 | 550 |

LNG40 | 1230 | 12300 | 48 | 600 | 40 | 5.00 | 800-850 | 550 |

LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.50 | 800-850 | 550 |

LNG48 | ALNICO5DG | 1280 | 12800 | 56 | 700 | 48 | 6.00 | 800-850 | 550 |

LNG52 | 1300 | 13000 | 56 | 700 | 52 | 6.50 | 800-850 | 550 |

LNG56 | ALNICO5-7 | 1300 | 13000 | 58 | 720 | 56 | 7.00 | 800-850 | 550 |

LNG60 | 1330 | 13300 | 60 | 750 | 60 | 7.50 | 800-850 | 550 |

LNGT28 | ALNICO6 | 1000 | 10000 | 56 | 700 | 28 | 3.50 | 800-850 | 550 |

LNGT30 | 1100 | 11000 | 56 | 700 | 30 | 3.75 | 800-850 | 550 |

LNGT18 | ALNICO8 | 580 | 5800 | 80 | 1000 | 18 | 2.25 | 800-850 | 550 |

LNGT32 | 800 | 8000 | 100 | 1250 | 32 | 4.00 | 800-850 | 550 |

LNGT38 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 800-850 | 550 |

LNGT44 | 850 | 8500 | 115 | 1450 | 44 | 5.50 | 800-850 | 550 |

LNGT48 | ALNICO8HE | 900 | 9000 | 120 | 1500 | 48 | 6.00 | 800-850 | 550 |

LNGT60 | ALNICO9 | 900 | 9000 | 110 | 1380 | 60 | 7.50 | 800-850 | 550 |

LNGT72 | 1050 | 10500 | 112 | 1400 | 72 | 9.00 | 800-850 | 550 |

LNGT80 | 1080 | 10800 | 120 | 1500 | 80 | 10.00 | 800-850 | 550 |

LNGT88 | 1100 | 11000 | 115 | 1450 | 88 | 11.00 | 800-850 | 550 |

LNGT96 | 1150 | 11500 | 118 | 1480 | 96 | 12.00 | 800-850 | 550 |

LNGT36J | ALNICO8HC | 700 | 7000 | 140 | 1750 | 36 | 4.50 | 800-850 | 550 |

LNGT48J | 800 | 8000 | 145 | 1820 | 48 | 6.00 | 800-850 | 550 |

LNGT52J | 850 | 8500 | 140 | 1750 | 52 | 6.50 | 800-850 | 550 |

烧结铝镍钴磁性能参数

Sintered AlNiCo Magnetic Property Table

牌号 Grade | 分类 MMPA CLASS | 剩磁 Br Residual Induction | 磁感矫顽力 Coercive Force | 最大磁能积 (BH)max Max Energy Product | 居里温度 Curie temperature | 工作温度 Working Temperature |

Br | Hcb | ( BH ) max | (Tc) | Tw |

mT | (kGs) | kA/m | (kOe) | kJ/m3 | (MGOe) | [℃] | [℃] |

Typ. | Typ. | Typ. |

FLN8 | S.ALNICO3 | 500 | 5000 | 40 | 500 | 8 | 1.00 | 760 | 450 |

FLN12 | S.ALNICO2 | 700 | 7000 | 48 | 600 | 12 | 1.5 | 810 | 450 |

FLNT18 | S.ALNICO7 | 600 | 6000 | 90 | 1130 | 18 | 2.2 | 860 | 450 |

FLN34 | S.ALNICO5 | 1200 | 12000 | 48 | 600 | 34 | 4.25 | 890 | 450 |

FLNT28 | S.ALNICO6 | 1050 | 10500 | 56 | 700 | 28 | 3.5 | 850 | 450 |

FLNT38 | S.ALNICO8 | 880 | 8800 | 120 | 1500 | 38 | 4.75 | 850 | 450 |

FLNT42 | S.ALNICO8 | 880 | 8800 | 120 | 1500 | 42 | 5.25 | 850 | 450 |

FLNT33J | S.ALNICO8HC | 700 | 7000 | 140 | 1750 | 33 | 4.13 | 850 | 450 |

Alnico magnets are manufactured either by casting or sintering. Alnico is produced by conventional foundry methods using resin bonded sand molds or powder metal manufacturing methods. Sintering Alnico is suitable for complex geometries.

Most Alnico produced is anisotropic meaning that the magnetic axle of the grains is oriented in one direction. The orientation is achieved by a heat treatment process after casting or sintering. The process involves heating the casting or sintered part above its Curie Temperature and then cooling it at a controlled rate in the presence of a directionalized magnetic field. Final shaping of the Alnico materials is achieved by abrasive grinding and cutting where close tolerances are required.

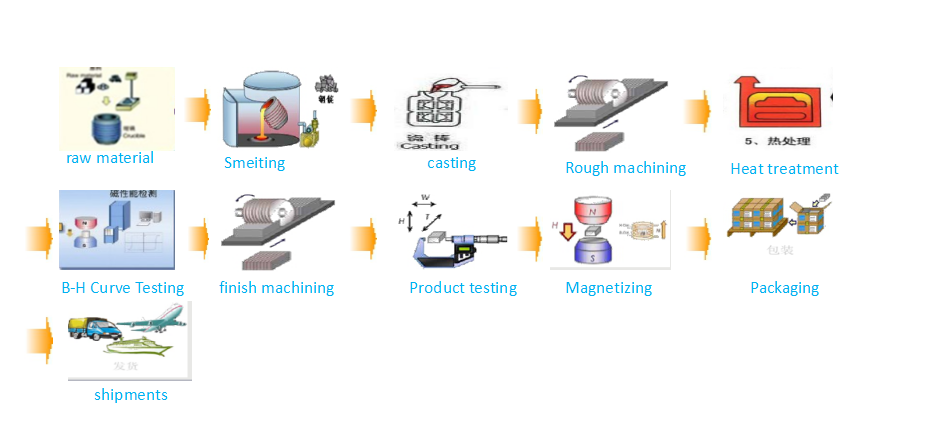

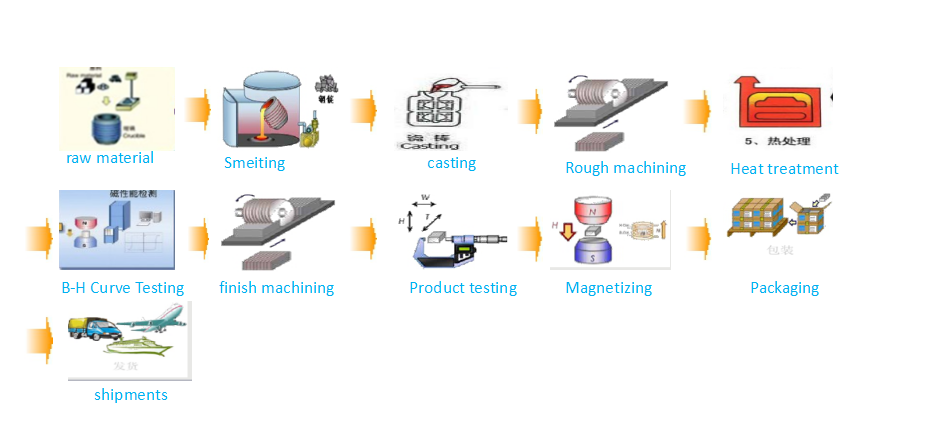

Cast AlNiCo Manufacturing process

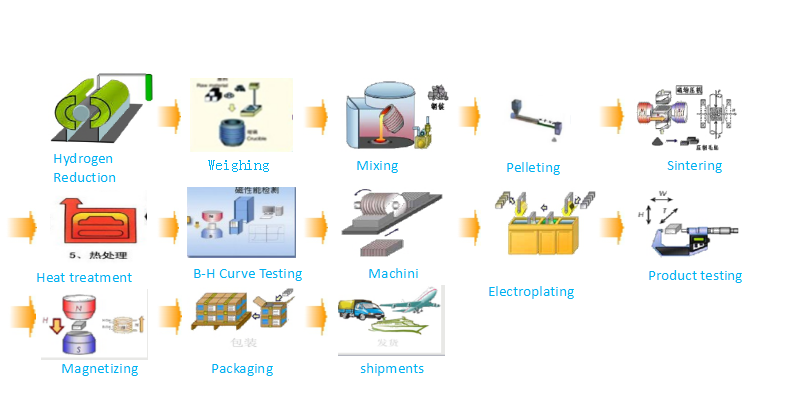

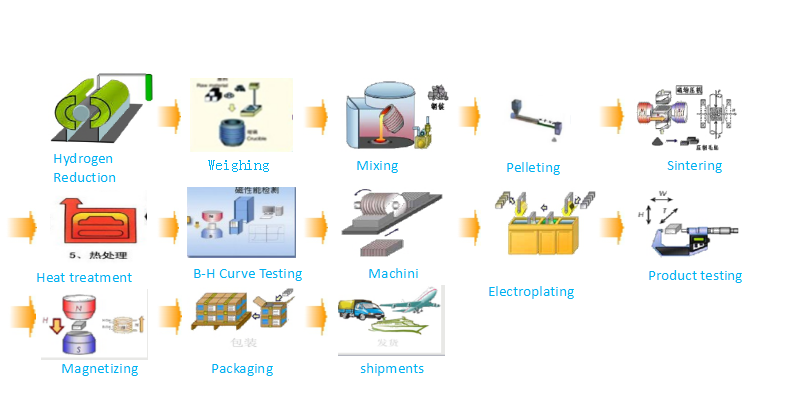

Sintered AlNiCo Manufacturing process

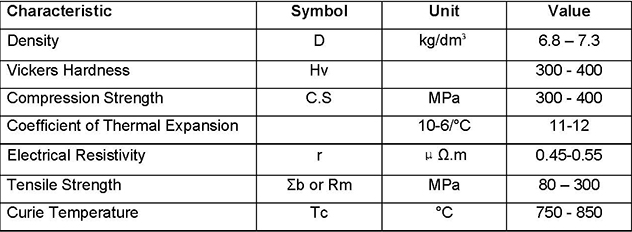

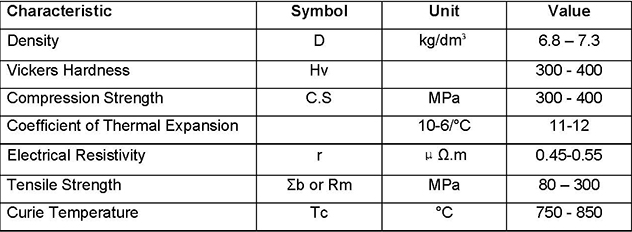

Physical Properties of Alnico magnets

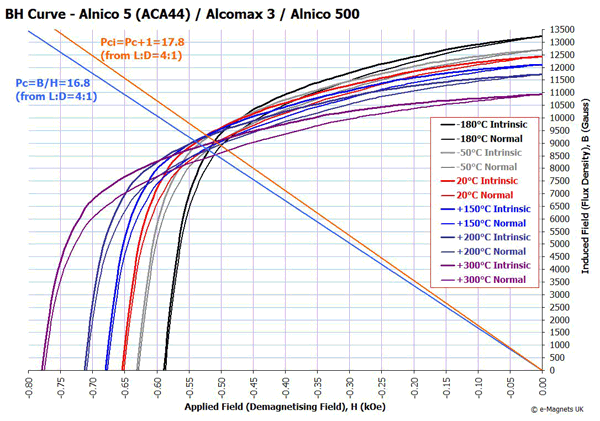

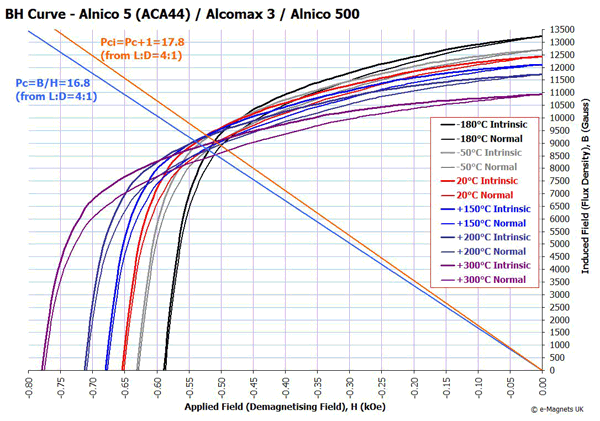

Cast AlNiCo Demagnetisation Curve